|

|

|

|

| |

[Close] |

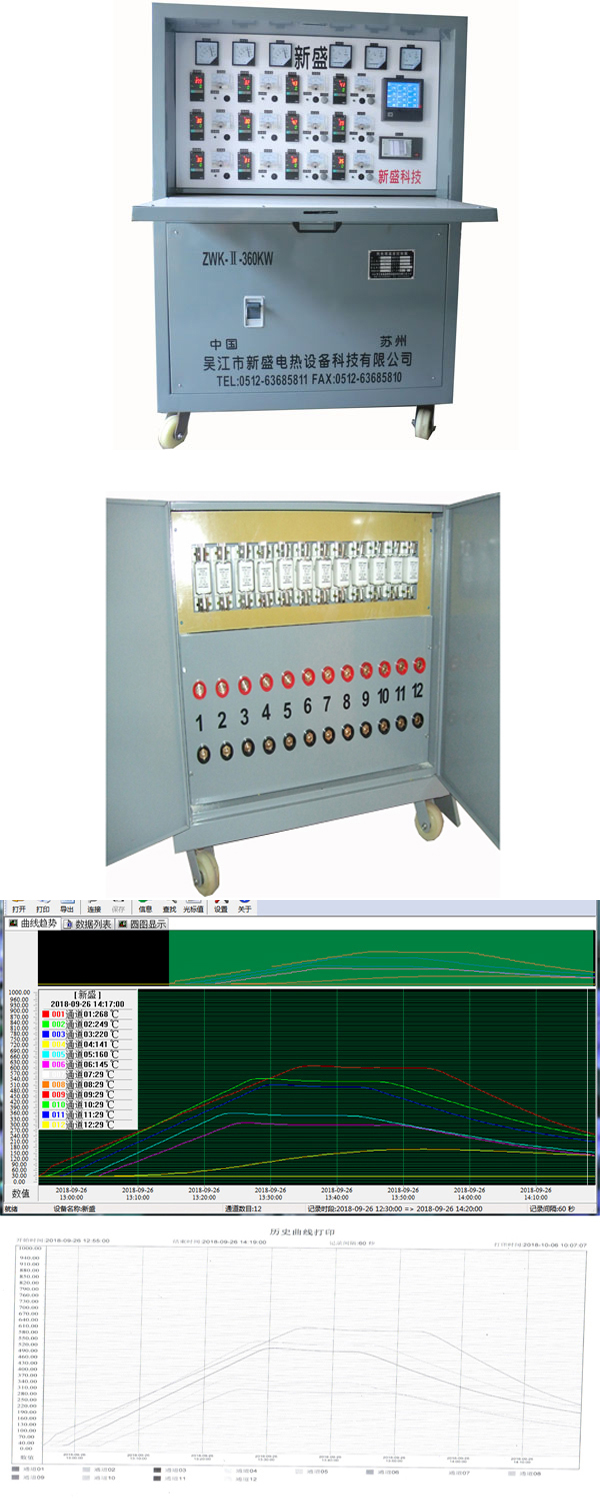

| ZWK/WCK-11-360KW no paper intelligent temperature control box |

Large installation engineering in the of site heat treatment, due to environment conditions is bad, and often missing maintenance technology and the accessories, according to this a features we design production has versatility strong, high performance \ high reliable of ZWK temperature control box. ZWK used international advanced of imports temperature program instrument, has program given function and since adapted control function, can by process temperature curve set and run, temperature automatically records, both can guarantee products quality, also can extended heater life. this machine can and various heater supporting, For preheating before welding and post weld heat treatment. output voltage of 220V, (0-220V), adjustable voltage.

Features:

1, three-button PXR5 Series intelligent microcomputer operation temperature controller

2, self-tuning and fuzzy PID control function accuracy up to ± 1 ℃

Paragraph 3, per point 8 slope setting/heating, insulation, cooling

4, over temperature, low temperature alarm indicator intuitive and reliable

5, SCR output is small, weighing about 250 kg

6 installation and maintenance, adaptation to high altitude, preheating hydrogen removal treatment

Performance:

Rated voltage is 380V (three phase and four wire)

Rated power: 360KW, temperature control point 12, checkpoint 12, the highest temperature 1000 ℃

With paperless temperature recorder replaces the traditional paper temperature logger

The output voltage is 220V, also can be configured according to customer''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''s actual demand surge features adjustable 0-220V

Device power 30KW,60KW,90KW,120KW,180KW,240KW,360KW

Model

Rated output power

(kw)

Temperature control points

Record points

ZWK/WCK-30-0101

30

1

1

ZWK/WCK-60-0306

60 3 6

ZWK/WCK-90-0306

90 3 6

ZWK/WCK-120-0612

120 6 12

ZWK/WCK-180-0612

180 6 12

ZWK/WCK-240-0612

240 6 12

ZWK/WCK-360-1212

360 12 12

Model description

Full metal components heat treatment equipment consists of three parts, namely ceramic electric heaters, temperature-controlled Cabinet and auxiliary materials.

1. Ceramic electric heaters: heating elements, heat source when the workpiece is heated. Our company provides you with a variety of models and specifications, they have different characteristics, and performance are not the same. Like LCD, SCD rope-type of track-type heater heater, NJ-heat-frame heater, general user requirements according to heating the workpiece shape, thickness and the temperature value that you want to select.

2. Temperature control box: is complete with ceramic electric heater, ceramic heater with power and control their working conditions so as to achieve the purpose of temperature control. Temperature control box is equipped with a temperature control device used to control, measure temperature and configuration of temperature logger for recording the temperature of the workpiece curves for user archiving records. At present, our company offers a variety of model specification temperature control box for the user, such as ZWK, WCK, RWK-Series intelligent temperature control box, DWK, TCS series computer temperature control box, LWK series temperature control box, user is required to type under the scope of heating, heating technology and site requirements to choose the ideal practical temperature control box.

3. Auxiliary material: main has KJ type fast received long wire (temperature control box and heater between distance of connection line, also for 36V, and 55V, and 110V, heater series with, and distribution has fast received plug), and thermocouple (temperature sensor, for measurement was heating artifacts of temperature), and compensation wire (thermocouple and temperature control box between distance of connection line), and silicate aluminum high temperature insulation cotton (block heat distributed).

Precautions for use:

1, must have reliable earthing of the workpiece to be heated.

2, heater when in use are not allowed to overlap.

3, thermocouple echo artifacts put even reliable.

Notes:

1, width of the heater should be 8-12 times the thickness of the object to be heated.

2, according to user needs to supply wire and cable, thermocouple, insulation materials and temperature control cabinets as well as capacitor welding apparatus.

3, power error is ± 3%, shape tolerance is ± 2%.

4, special specification can be specially ordered. |

|

|

|